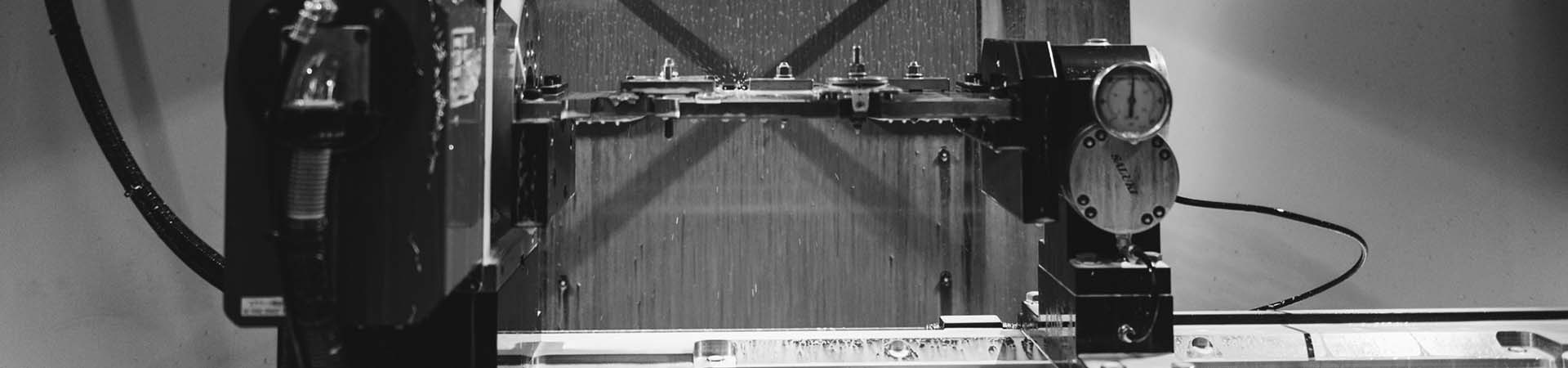

Sand Casting Process

The Sand casting process offers simple medium for production, sand castings are suitable in all Aluminium, Zinc, and Copper Alloys.

The sand casting process is chosen for the production of, small numbers of castings for complex shaped casting requiring intricate cores and large non ferrous castings.

Advantages of sand casting include:

- low tooling costs

- largest casting sizes achievable

- very low gas porosity is possible

- general versatility of the process is good

The Sand casting process is the most popular casting process employed in industry. In general the sand used in making sand castings has fine, round grains that can be closely packed to form a smooth surface.

The sand casting process involves pouring molten zinc, aluminium or copper into a sand mould.

The designer should take into account the limitations of the sand casting process such as low casting rates, a 3-5mm minimum wall thickness, poor linear tolerance (e.g. 4mm/m.) and coarse grain size. As well as other considerations such as the finish and machining allowances.

MRT Casting offer a one-stop die casting shop, getting us involved at the beginning stage of designing your casting component can save you time and money.

Get more information on the different casting processes including high pressure and gravity die casting processes or contact us today for expert casting process advice

Enquire About Our Sand Casting Process

Notes for Designers of Non-Ferrous Castings

DOWNLOAD NOW Guides

HOW can MRT Castings help you?

I want...

- Select what you need

- a complete solution

- to develop a new component from initial concept

- advice on what processes are best suited to my component

- prototypes before committing to production tooling

- to re-shore production to the UK from overseas

- a new supplier to use existing tooling

- to convert a machined from solid part to a casting

- a supplier who can meet stringent quality requirements

New at MRT Blogs

We’re all enjoying the summer weather right now, but at MRT we’re putting the sunshine to great use.

Read MoreWe're excited to announce that MRT Castings will be exhibiting again at Southern Manufacturing & Electronics!

Read MoreMRT Secure Cyber Essential Plus Standard

17th Jul 2023

MRT Castings is proud to announce that it has achieved certification to the ‘Cyber Essentials Plus’ standard.

Read More