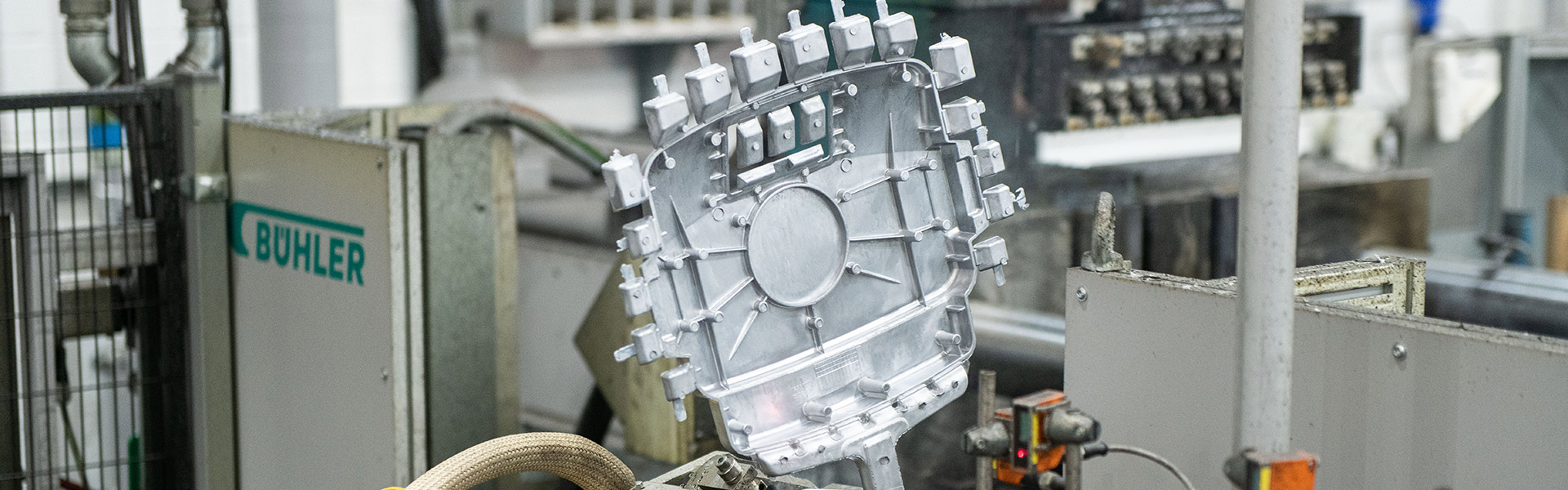

Automotive Aluminium Die Castings

MRT are an established casting partner to leading Automotive OEMs and their Tier One suppliers.

Our automotive castings include structural hinge castings, engine components, electronic enclosures, and interior trims. MRT’s components can be found on high performance sports cars, vintage cars, and commercial vehicles.

Capabilities for Automotive OEMs

We are well acquainted with the rigorous validation and process control requirements of the automotive industry, and have highly robust systems in place to control materials, change management and component certification.

Client quality teams are always welcome to visit our world-class manufacturing facilities for audits and manufacturing reviews.

During component development MRT offer industry leading simulation and design tools to optimise your component for manufacture. This cuts development time and minimises design changes after initial sampling.

Continuous investment in our UK foundry and CNC machining facility has positioned MRT among the most technically advanced and highly flexible diecasting facilities in Europe for the production of automotive components.

Applicataions in Automotive

Cast components destined for the automotive industry are wide ranging and include engining mounting brackets, hinge castings for doors, bonnets and boots, interior trim housings, electronic module enclosures, structural components for high-performance vehicles... to name just a few.

Why Choose MRT for Automotive Components

Our combination of diecasting and CNC machining provides the speed and economy of casting, and the precision and repeatability of machining.

We have a long and proven track record in the automotive market, where we deploy aluminium alloys such as LM6 and LM25 to great effect.

High pressure aluminium die casting is ideal for thin walled, lightweight enclosures and trim panels. Our gravity diecasting process is well suited for structural components including brackets, hinges, and engine components.

A comprehensive range of surface finishing processes ensures MRT can provide a one-stop-shop for finished cast components complete and ready for your assembly line.

Our flexible manufacturing processes, and can-do approach ensure we can respond quickly to changes in demand, or for compressed time-scales on product launches.

Request a quote for your automotive casting component.

Gallery

Why Choose MRT?

Why Choose MRT?

- Wide experience in Automotive component manufacture

- Supply leading UK and European OEMs and Tier One Suppliers

- Continual investment in UK foundry and CNC machining facility

- Gravity Diecasting, High Pressure Diecasting and CNC Machining from one source

- Offer industry leading simulation

- Comprehensive design for manufacture support

- Offer a wide range of surface finishing processes

- Work to short lead times

Related Articles

HOW can MRT Castings help you?

I want...

- Select what you need

- a complete solution

- to develop a new component from initial concept

- advice on what processes are best suited to my component

- prototypes before committing to production tooling

- to re-shore production to the UK from overseas

- a new supplier to use existing tooling

- to convert a machined from solid part to a casting

- a supplier who can meet stringent quality requirements

New at MRT Blogs

Looking Ahead to 2026 at MRT Castings

19th Jan 2026

As we begin the new year, it’s a great opportunity to reflect on the progress made at MRT over the past 12 months.

Read MoreWe're pleased to share that MRT Castings will once again be exhibiting at Southern Manufacturing & Electronics

Read MoreOnce again, MRT Castings have partnered with Brother and their UK agent, Whitehouse Machine Tools – a relationship that has spanned more than 25 years.

Read More