About Us

MRT Castings have been at the forefront of non-ferrous casting projects for more than 75 years.

Founded in 1947, ours is a privately-owned, family-run business of international renown with reputation forged around a fully integrated manufacturing service, from design right through to assembly and logistics.

Woking out of our state-of-the-art facility in Andover, we have a rich history of developing cast components for the aerospace, defence, medical and electronics industries – to name just a few.

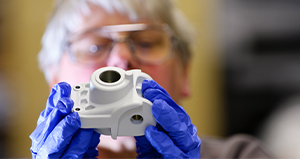

We are proudly certified to ISO quality standards and committed to rigorous quality control that encompasses cosmetic inspection and non-destructive testing for the most critical parts.

Continued investment in technology, facilities and lean manufacturing enables us to regularly increase capacity, improve efficiencies and reduce lead times, meeting the demands of OEMs and Tier One clients the world over.

Experts in all things aluminium, and zinc, our team deploy a wide range of techniques including both gravity and high pressure die casting. This sets us up to handle both large and small volume work whilst offering strong engineering support throughout all product developments.

Your go-to die casting, machining and finishing specialists, we’re the ideal partner for your next manufacturing project.

MRT Castings - CERTIFICATIONS:

HOW can MRT Castings help you?

I want...

- Select what you need

- a complete solution

- to develop a new component from initial concept

- advice on what processes are best suited to my component

- prototypes before committing to production tooling

- to re-shore production to the UK from overseas

- a new supplier to use existing tooling

- to convert a machined from solid part to a casting

- a supplier who can meet stringent quality requirements

New at MRT Blogs

Looking Ahead to 2026 at MRT Castings

19th Jan 2026

As we begin the new year, it’s a great opportunity to reflect on the progress made at MRT over the past 12 months.

Read MoreWe're pleased to share that MRT Castings will once again be exhibiting at Southern Manufacturing & Electronics

Read MoreOnce again, MRT Castings have partnered with Brother and their UK agent, Whitehouse Machine Tools – a relationship that has spanned more than 25 years.

Read More