Looking Ahead to 2026 at MRT Castings

As we begin the new year, it’s a great opportunity to reflect on the progress made at MRT over the past 12 months. By the same token, we’re keen to share some up-and-coming developments for 2026, which promise to bring even more advantages to our customers.

Strengthening Capability Across the Foundry and Machine Shop

2025 was another year of focused investment at MRT, guided by the needs of the markets we support.

Within the foundry, we developed a number of new casting projects which have broadened both our technical capability and production capacity. Among these was the manufacture of the largest aluminium gravity diecastings in the company’s history, demonstrating our ability to support larger, more demanding component designs without risking any compromise to quality.

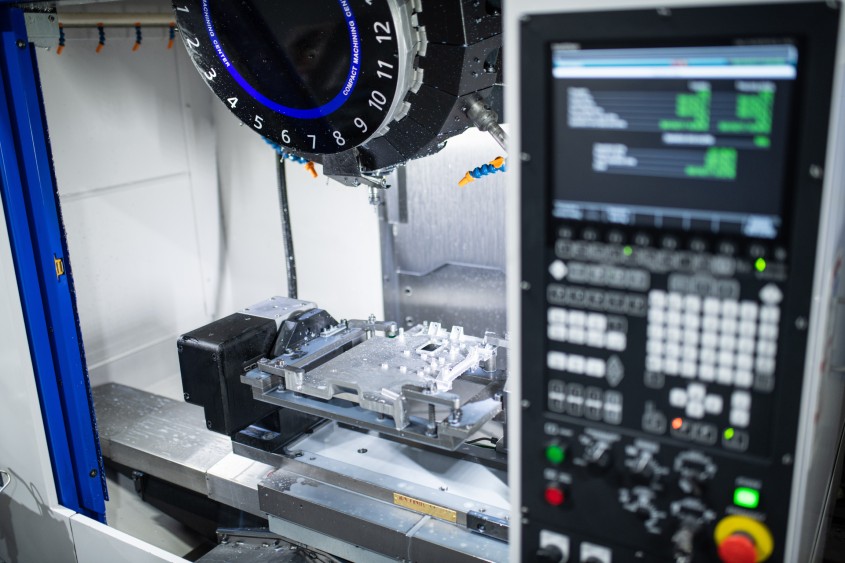

Moreover, in the machine shop, we further advanced our 5-axis machining capability with the addition of a Brother U500Xd2 CNC machining centre. Selected for its precision, speed and flexibility, the new machine is finely tuned for the accurate, high-productivity machining of complex cast components.

Investing in Facilities and Sustainability

Another major milestone in 2025 was the completed refurbishment of our former foundry building, now reopened as Unit 4.

Launched in April, the facility provides a dedicated, purpose-designed home for vibratory finishing, inspection and stockholding. This has empowered the MRT team to further improve workflow and deliver even greater quality control.

Furthermore, Unit 4 represents a major step forward in MRT’s journey to Net Zero. The building is home to our first PV solar installation, which currently generates around 25% of the electricity currently consumed by our machining facility. Alongside a range of energy-efficiency measures, the refurbishment has resulted in an A+ EPC rating. This is, without doubt, a mighty achievement for a building that served as our diecasting foundry for more than 50 years before operations moved to our new foundry site in 2021.

Collaboration Driving New Projects in 2026

Looking to the year ahead, we are working with several important new customers to bring exciting new projects to market, all of which are the result of close collaboration between our engineering team and our clients. Our design and simulation capabilities are helping us to stretch technical boundaries to develop even more complex, lightweight, high-performance components for a wide range of applications.

The engineering challenges ahead are exactly the kind we enjoy solving!

Meeting Customers Face to Face

The team is also looking forward to Southern Manufacturing & Electronics in February, where we’ll be catching up with existing customers and meeting new contacts. As always, the show provides the perfect setting for practical, technical conversations around component performance, manufacturability and supply-chain resilience.

You’ll find us on Stand C240 – we look forward to seeing you there!

Register For Your Free Visitor Pass

Here’s to another exciting year at MRT Castings. If you’ll be launching a new project in 2026 and are wondering if we can help, just drop us a line.

Contact us today to find out how we can support you with your next project.

HOW can MRT Castings help you?

I want...

- Select what you need

- a complete solution

- to develop a new component from initial concept

- advice on what processes are best suited to my component

- prototypes before committing to production tooling

- to re-shore production to the UK from overseas

- a new supplier to use existing tooling

- to convert a machined from solid part to a casting

- a supplier who can meet stringent quality requirements