Zinc Die Casting can be carried out via High pressure or Gravity Casting Methods.

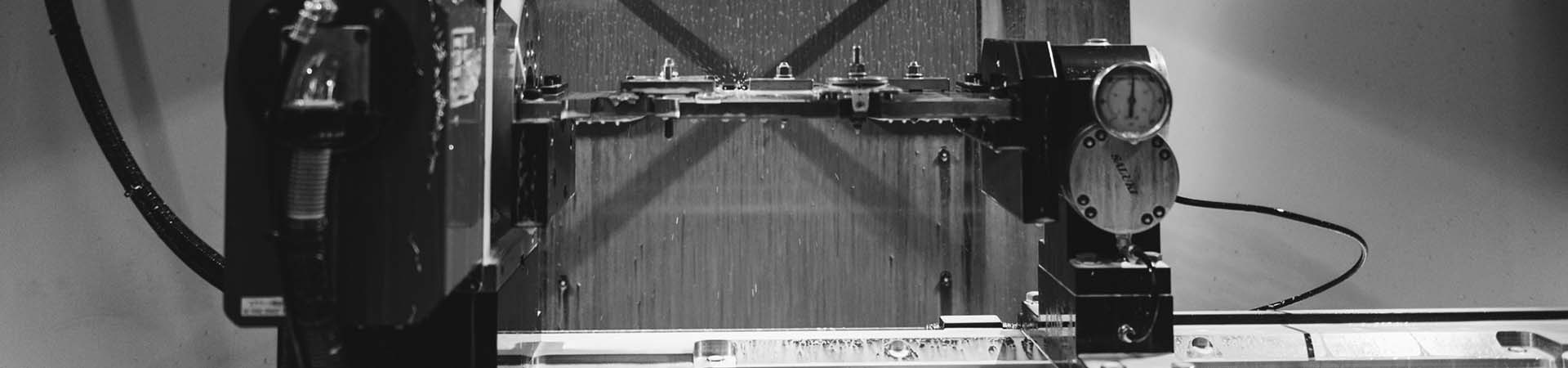

The High Pressure Zinc die casting process allows fast, precise, cost effective production of zinc die castings. Other benefits include:

- Locking forces of between 220 and 530 tonnes.

- Microprocessor control

- Computerised real-time shot control

- Automatic ladling and die-spray

- Automatic casting extraction and cooling.

MRT also have a range of microprocessor controlled hydraulic gravity zinc die casting machines, which mechanise movements of the die, increasing production rates, and improving consistency.

Other benefits include:

- Tilt pouring

-

Hydraulic movement on up to four axes

Contact our team of experts today for more information

ZINC DIE CASTING FORM

|

|

HOW can MRT Castings help you?

I want...

- Select what you need

- a complete solution

- to develop a new component from initial concept

- advice on what processes are best suited to my component

- prototypes before committing to production tooling

- to re-shore production to the UK from overseas

- a new supplier to use existing tooling

- to convert a machined from solid part to a casting

- a supplier who can meet stringent quality requirements

New at MRT Blogs

We're pleased to share that MRT Castings will once again be exhibiting at Southern Manufacturing & Electronics

Read MoreOnce again, MRT Castings have partnered with Brother and their UK agent, Whitehouse Machine Tools – a relationship that has spanned more than 25 years.

Read MoreAt a time when young engineering talent is in short supply, MRT Castings is taking a proactive approach to recruitment.

Read More